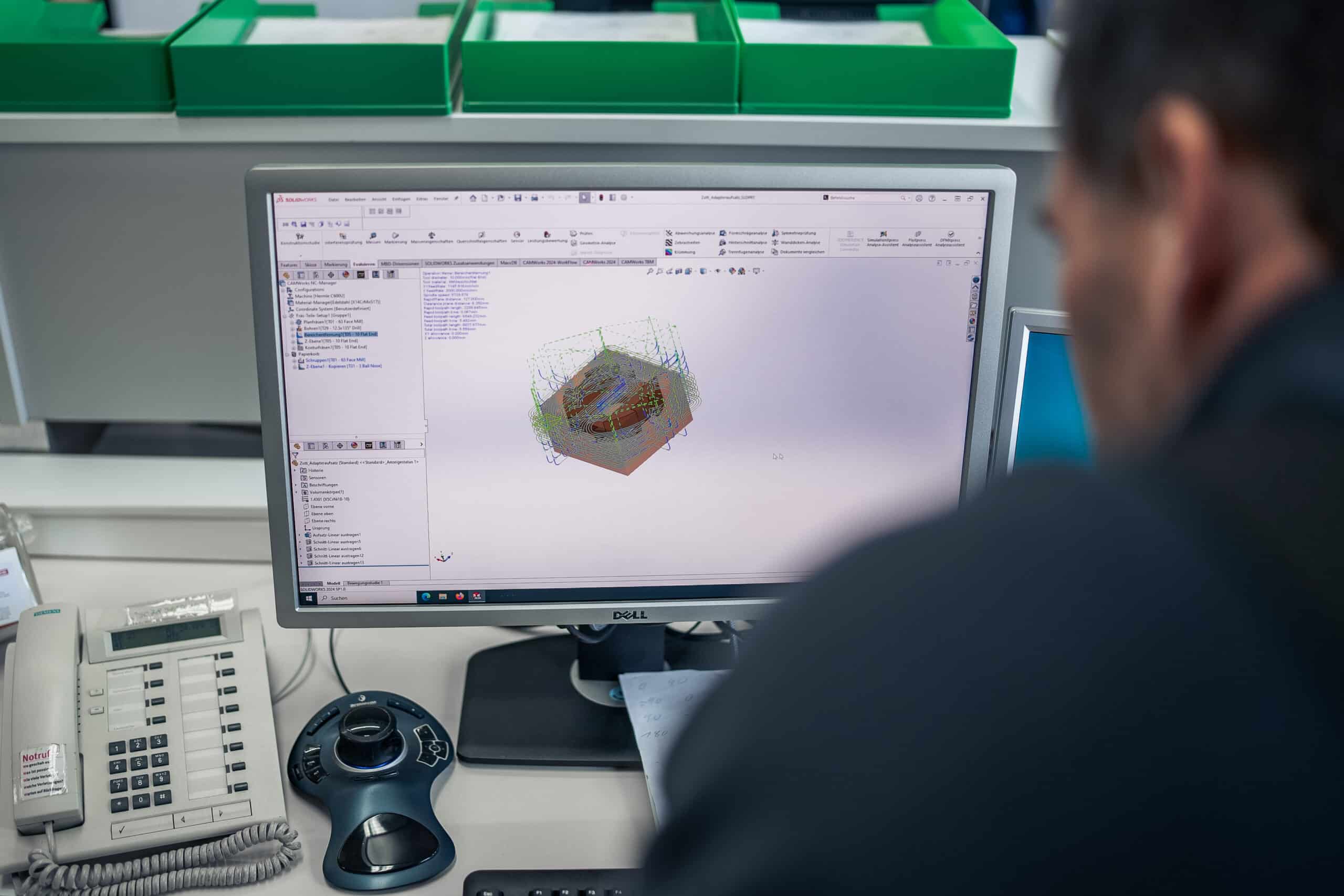

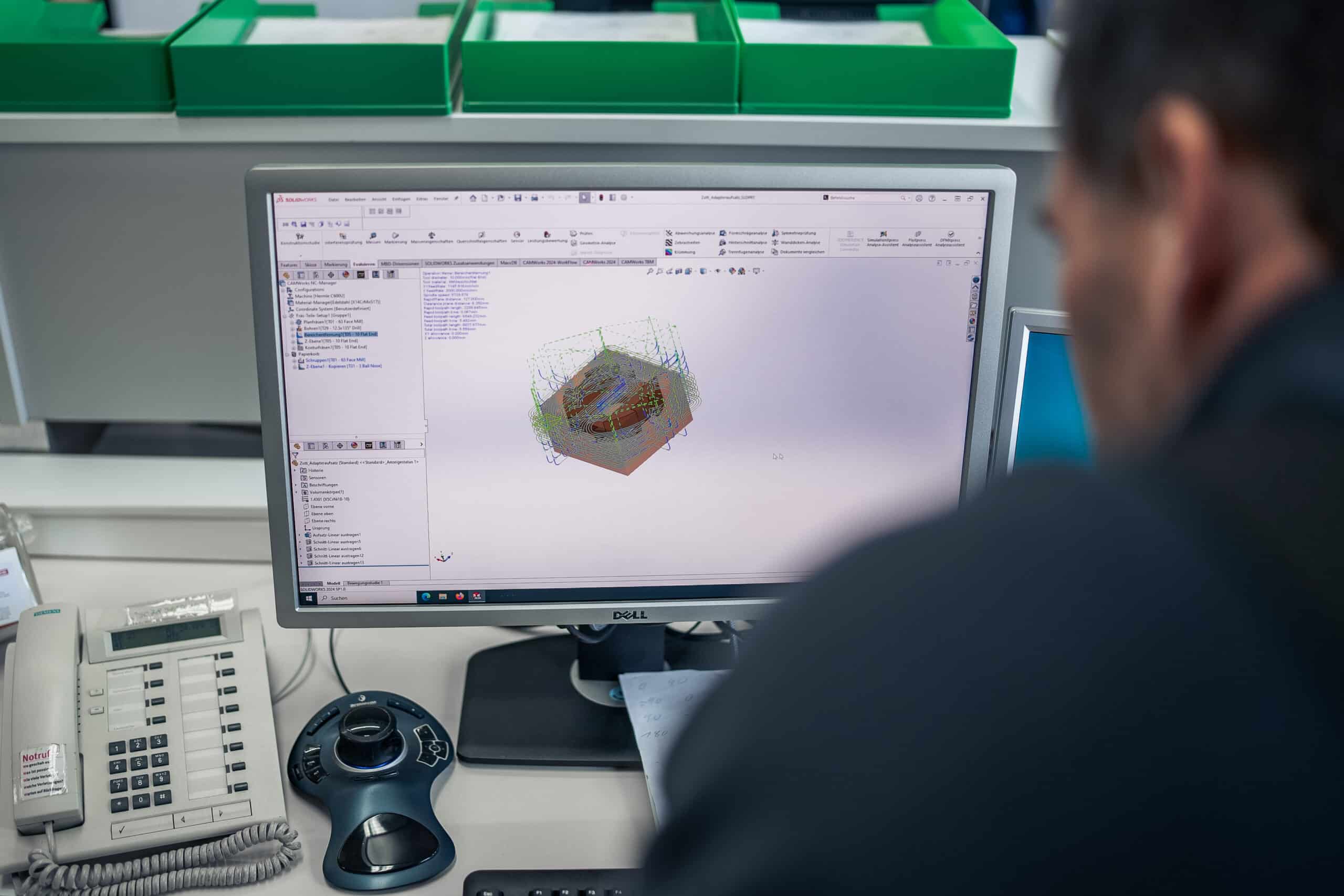

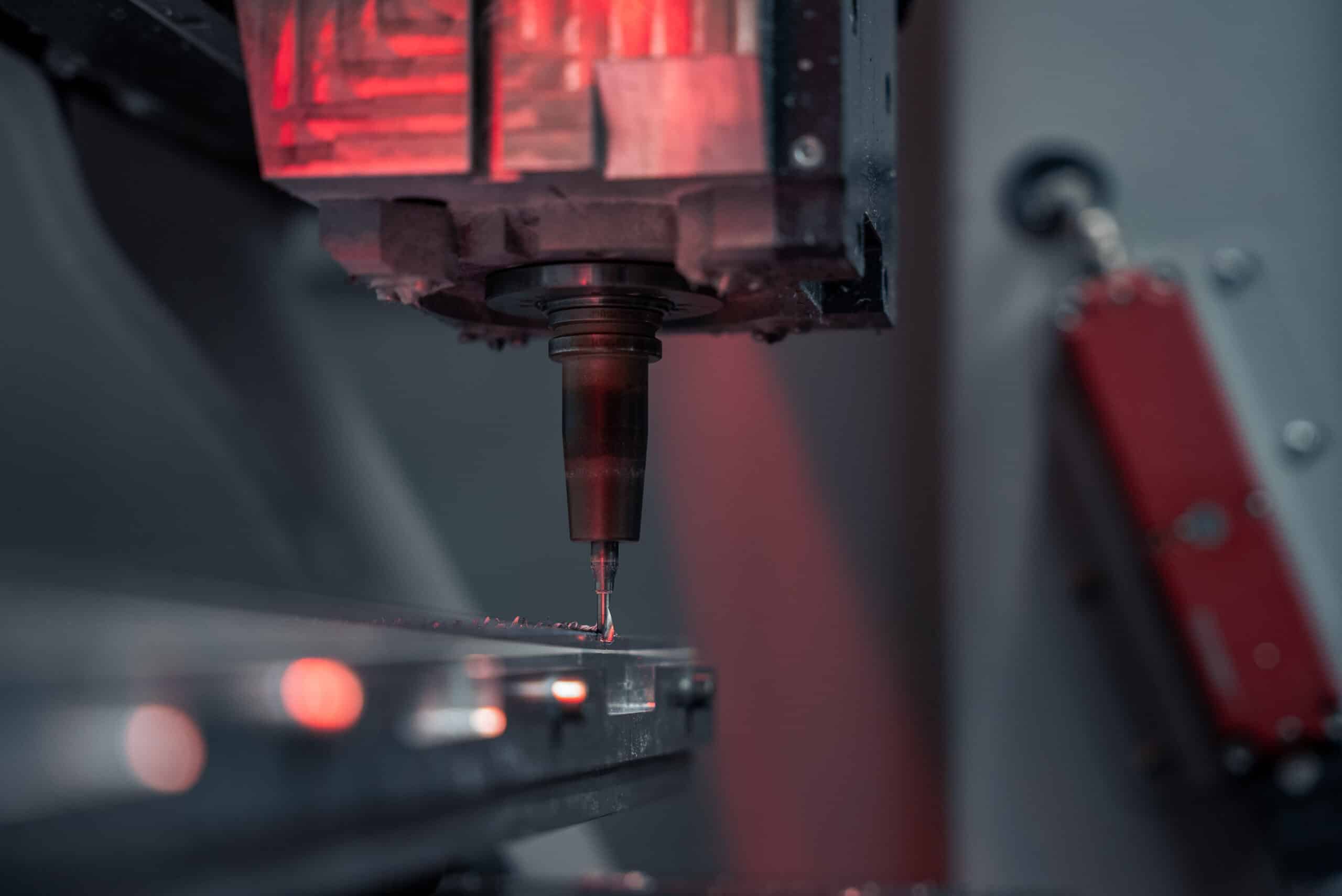

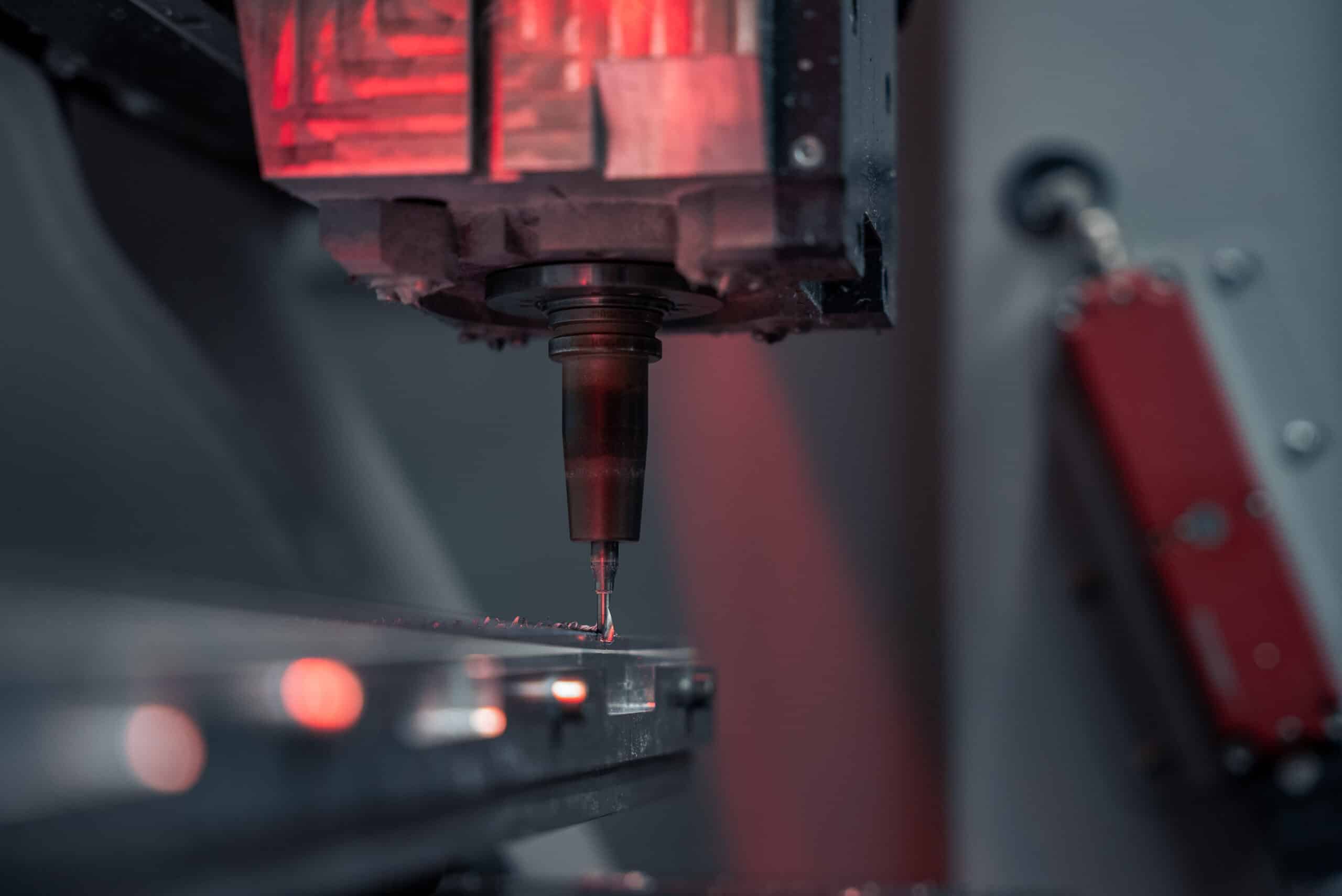

Our integrated in-house concept combines a wide range of services under one roof. This specifically includes development services for electronics as well as hardware and software.

Our integrated in-house concept combines a wide range of services under one roof. This specifically includes development services for electronics as well as hardware and software.